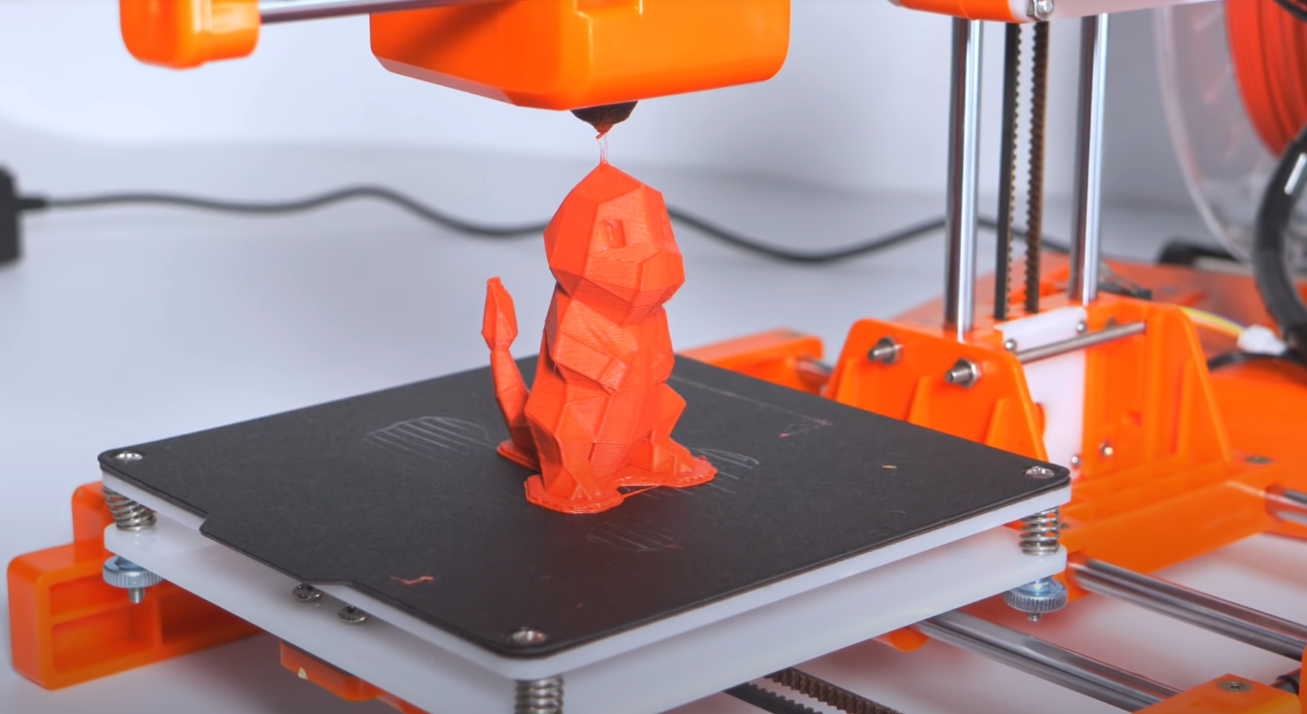

FDM printing is also a speedy process, and the technology can cost-effectively print objects in low quantities. Once you calibrate your printer and upload your CAD file, the printing process begins with just a push of a button. One advantage of using FDM is that three-dimensional printing models are easy. The FDM printing process is widely used at the consumer level.

You will understand how their different 3D printing technologies and mechanisms affect the quality of their print output. This article will discuss the differences in various types of 3D printers, especially in terms of their printing accuracy and their ability to print fine details. With resin printers, you can choose layer height options from 25 to 300 microns.

Resin 3D printers like DLP and SLA can print much smaller details as it offers very fine Z resolutions.

But as to how small your 3D printer can go, it depends mainly on its technology.Īn FDM 3D printer can print 3D models as small as its nozzle diameter, which is at least 0.15 millimeters. Using your 3D printer in creating very small models or models with very fine features and details may involve a steep learning curve for new users. Printing small-scale 3D models with a 3D printer may be challenging because resolutions are not the same as the resolutions you use for two-dimensional pictures and for printing images on paper.

0 kommentar(er)

0 kommentar(er)